A4-A6 up to 60 kW

Download

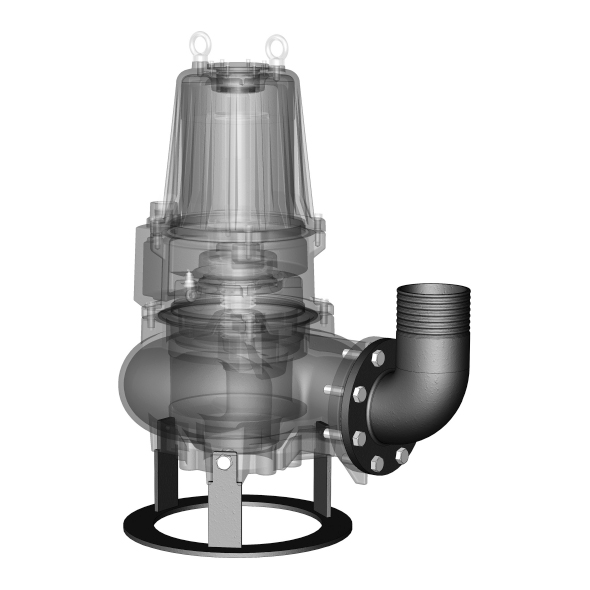

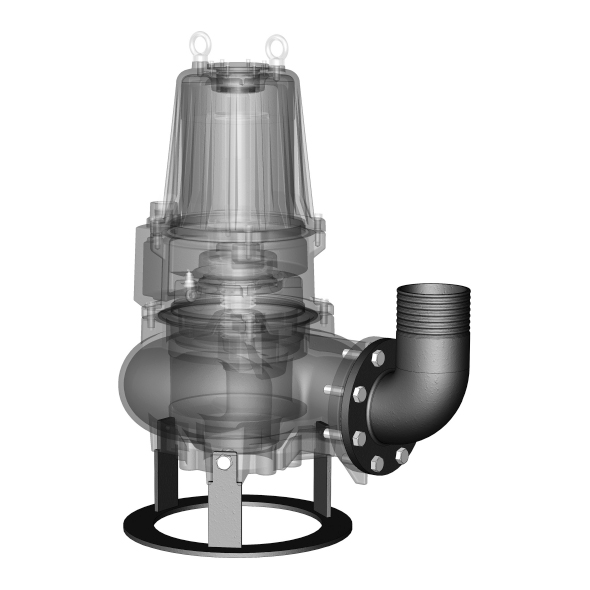

Product description

Product description

Application

The A4 – A6 poles Series is used to pump clear liquids and sewage. The wide range and high hydraulic efficiency renders this series particularly suited to water treatment plants, sewers, farming and industrial plants including in airports, underground public transport, hospitals and hotels.

Characteristic

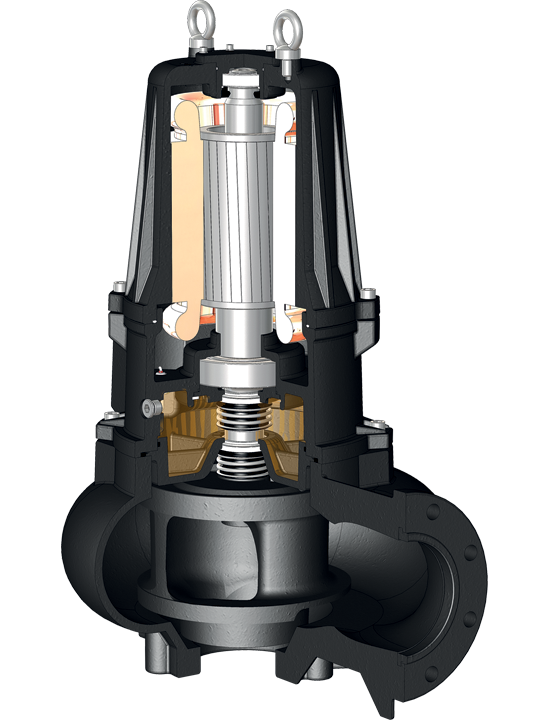

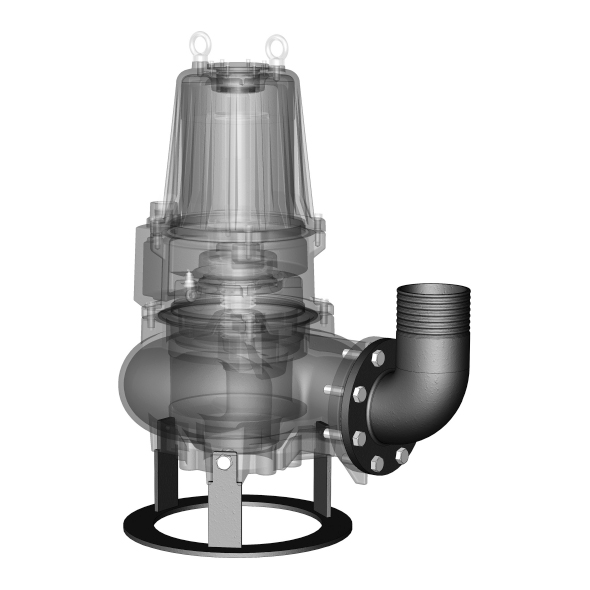

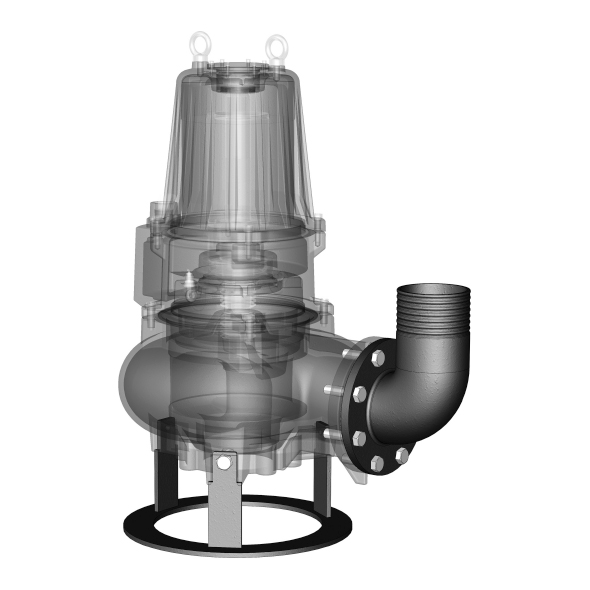

All main components are made of grey cast iron GG25. Two individual mechanical seals (motor side in the oil chamber, impeller side in contact with the liquid) and high quality parts, ensure the perfect functioning and reliability of the product.

Motor range

- Squirrel cage motor 4 -6 poles

- Thermal protection T1 and T2 embedded in the motor winding (to be wired to the three pole contactor in the control panel)

- Class F insulation (155°C)

- IP 68 protection

Motor cooling

The cooling of the motor is ensured by the liquid where the pump is submerged.

Limits of use

- Max. permissible liquid temperature: 40°C with pump fully submerged

- On request, special version (excluded ATEX) to withstand liquid temperature up to 60°C with pump fully submerged, no S1 service

- Maximum depth of immersion: 20 mt.

- Permissible pH value: 6-10

- Hydraulic features suitable for liquids with density <1,1 kg/dm3

- Allowed voltage: 400V – 690V ±5%

- Allowed frequency: 50Hz ±2%

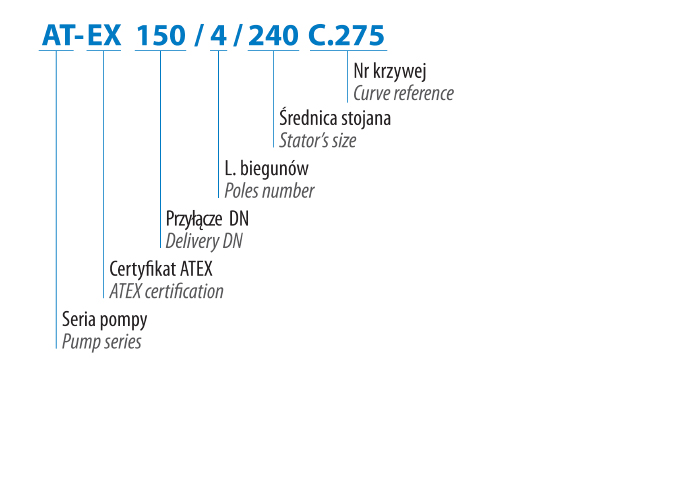

Marking legend

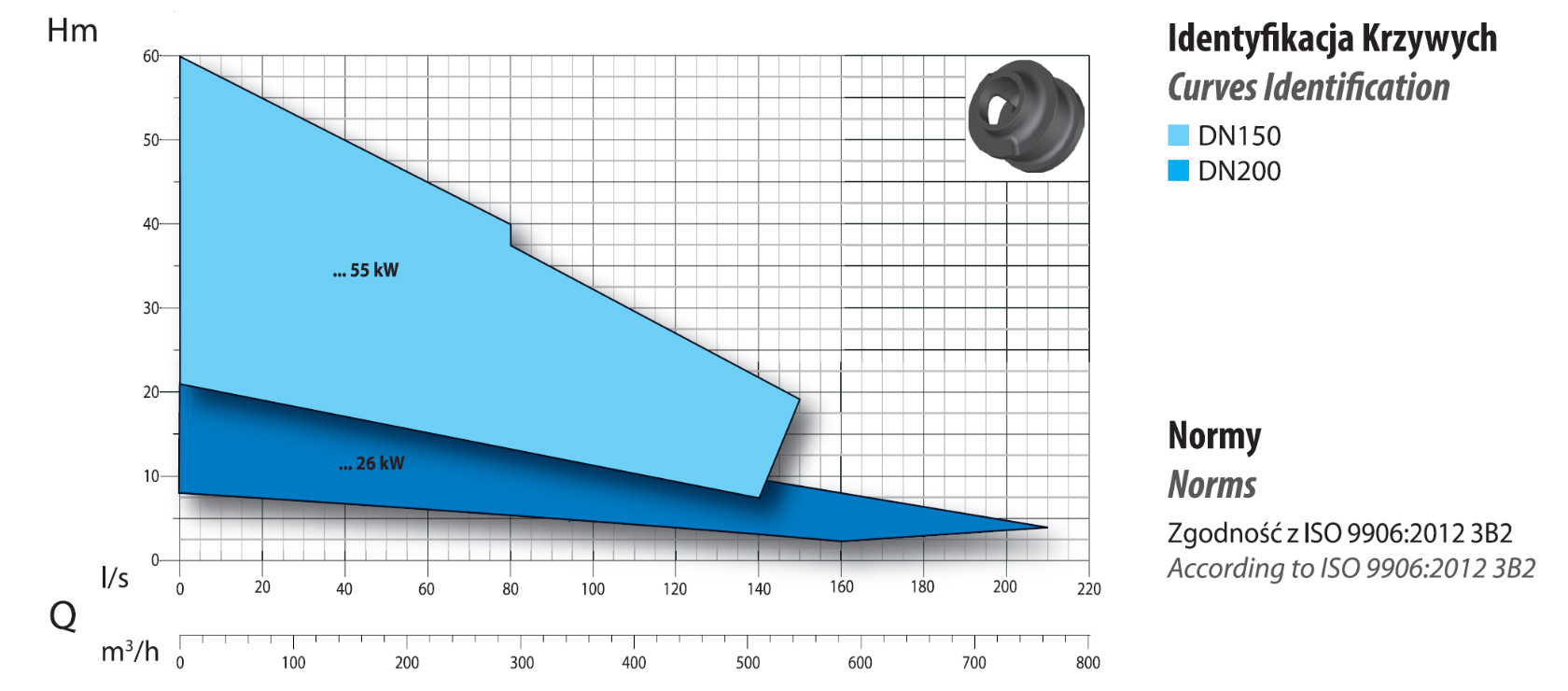

Performance Overview

List of components and materials

Stainless steel AISI 416

Cast iron GG25

Cast iron GG25

Stainless steel 420

Cast iron GG25

Silicon/Carbide (SIC/SIC/Viton)

Cast iron GG25

Silicon/Carbide (SIC/SIC/Viton)

Cast iron GG25

Cast iron GG25

Technologies and solutions

Impellers

This range of pump features close double channel impeller with excellent performance and free passage of solids up to 130 mm.

Explosion proof pumps

These certificates grant for the safe use of the product in hazardous area in line with the stringent European and International standards ATEX/IECEx.

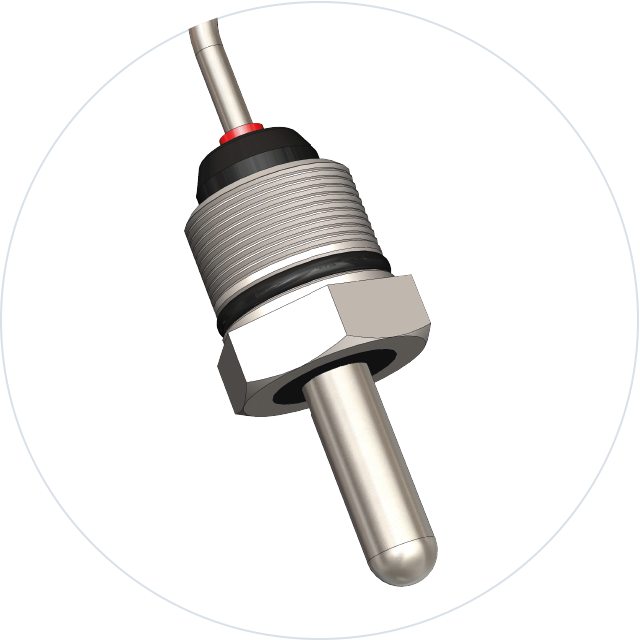

Seal leak detector

The seal leak detector is certified according to the norm EN 60079-0, EN 60079-1 (through safety barrier) and fitted standard on all series (not applicable with IECEx)..

Bearings

The series is fitted with a cylindrical roller bearing (upper bearing) to absorb the thrust and vibration generated by the pump shaft.

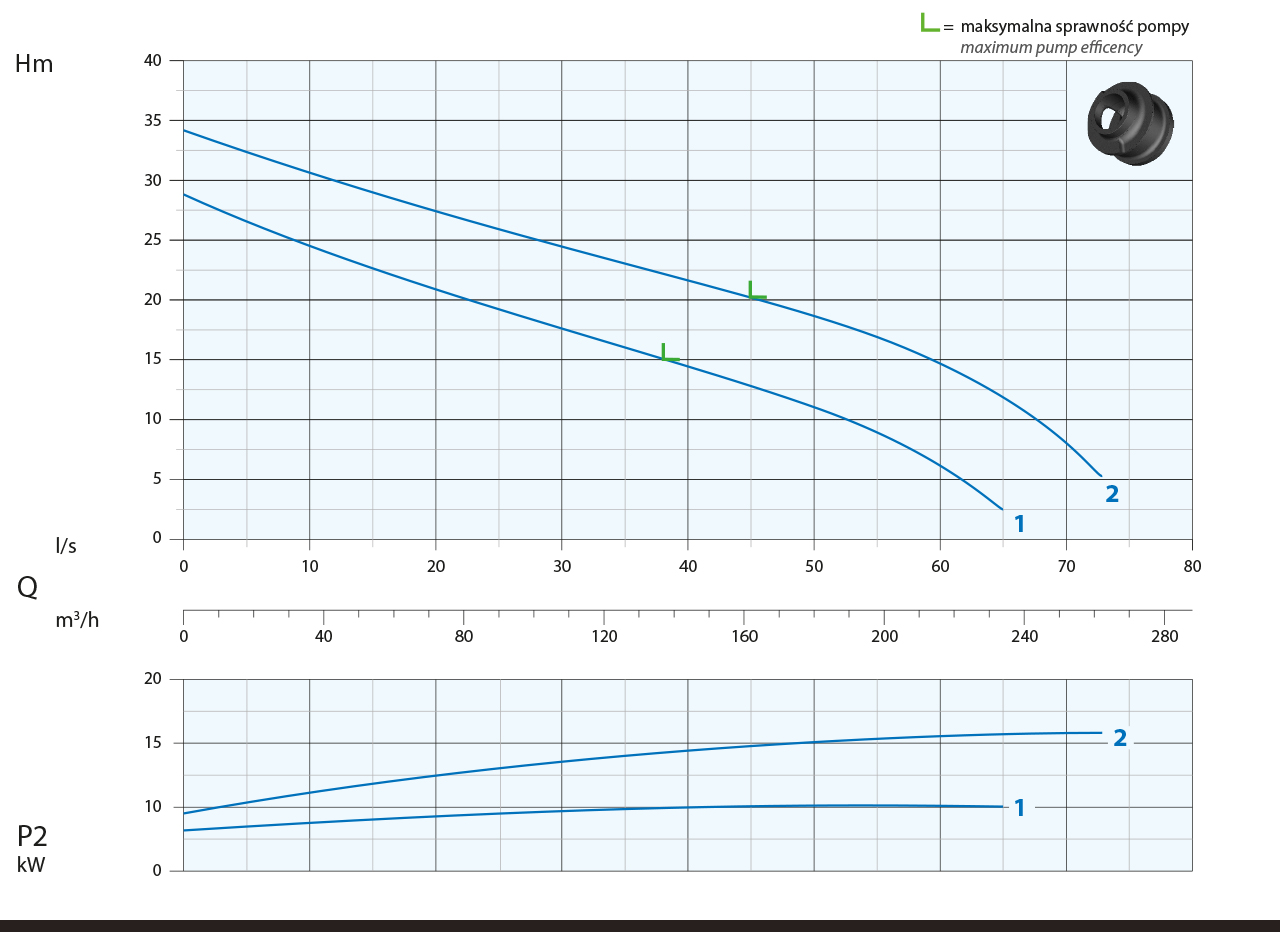

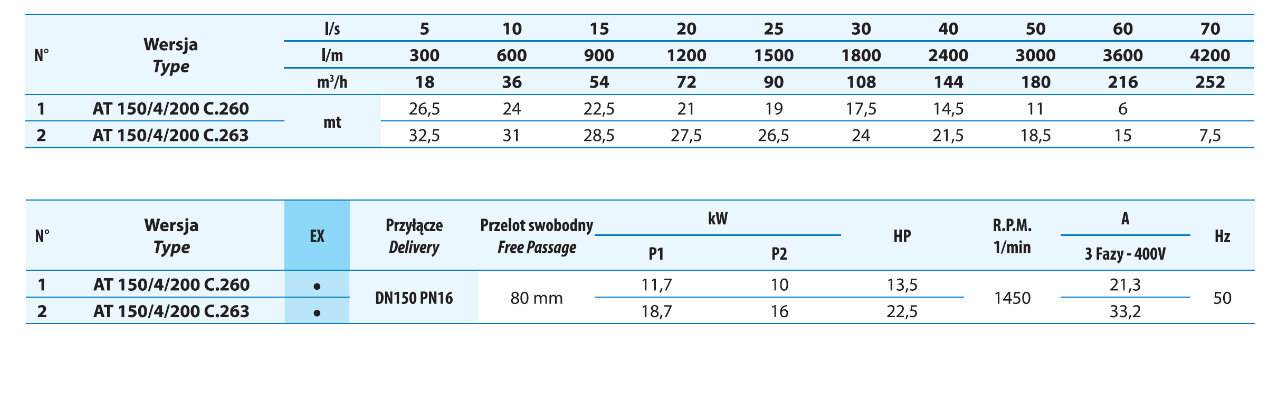

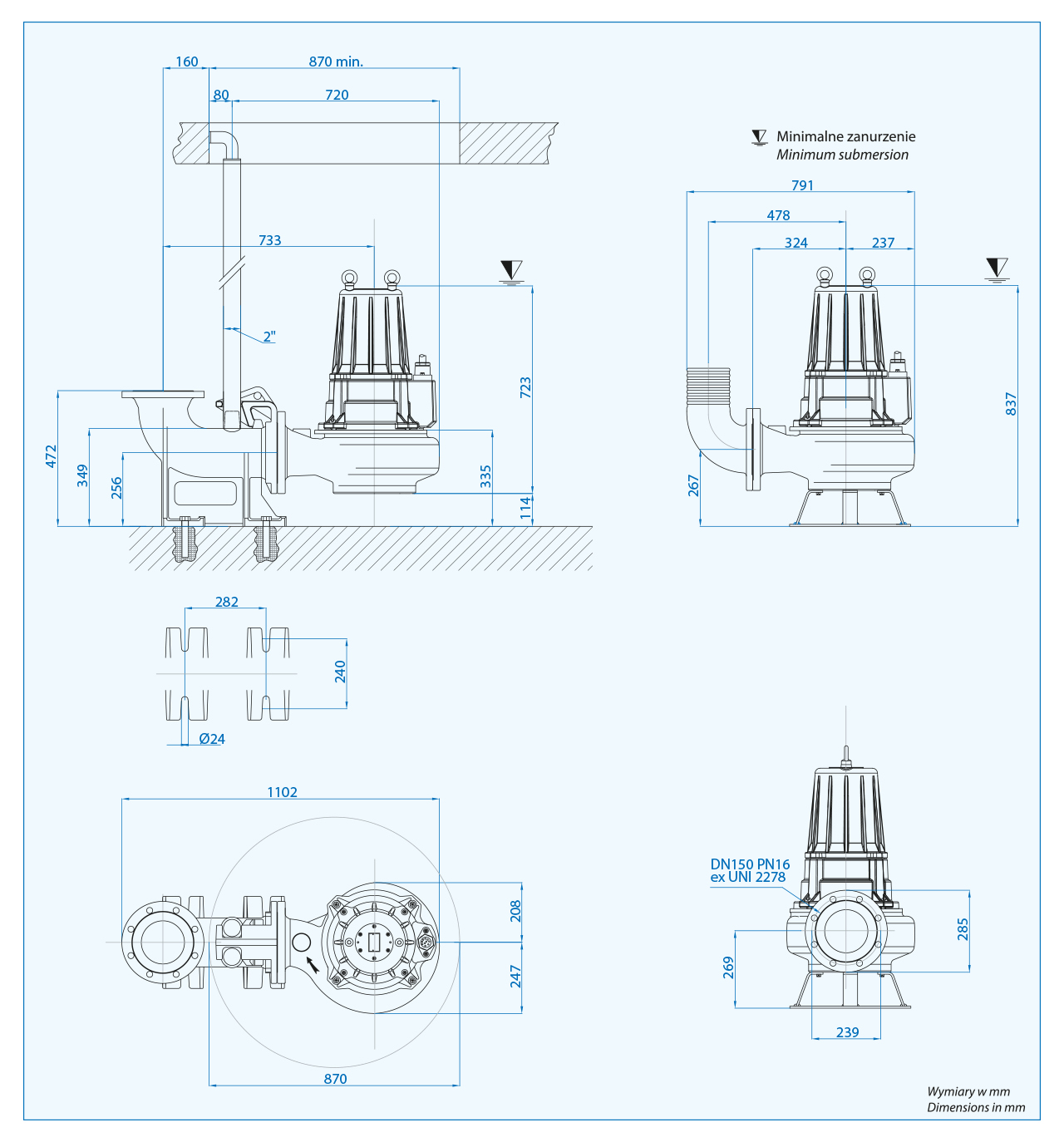

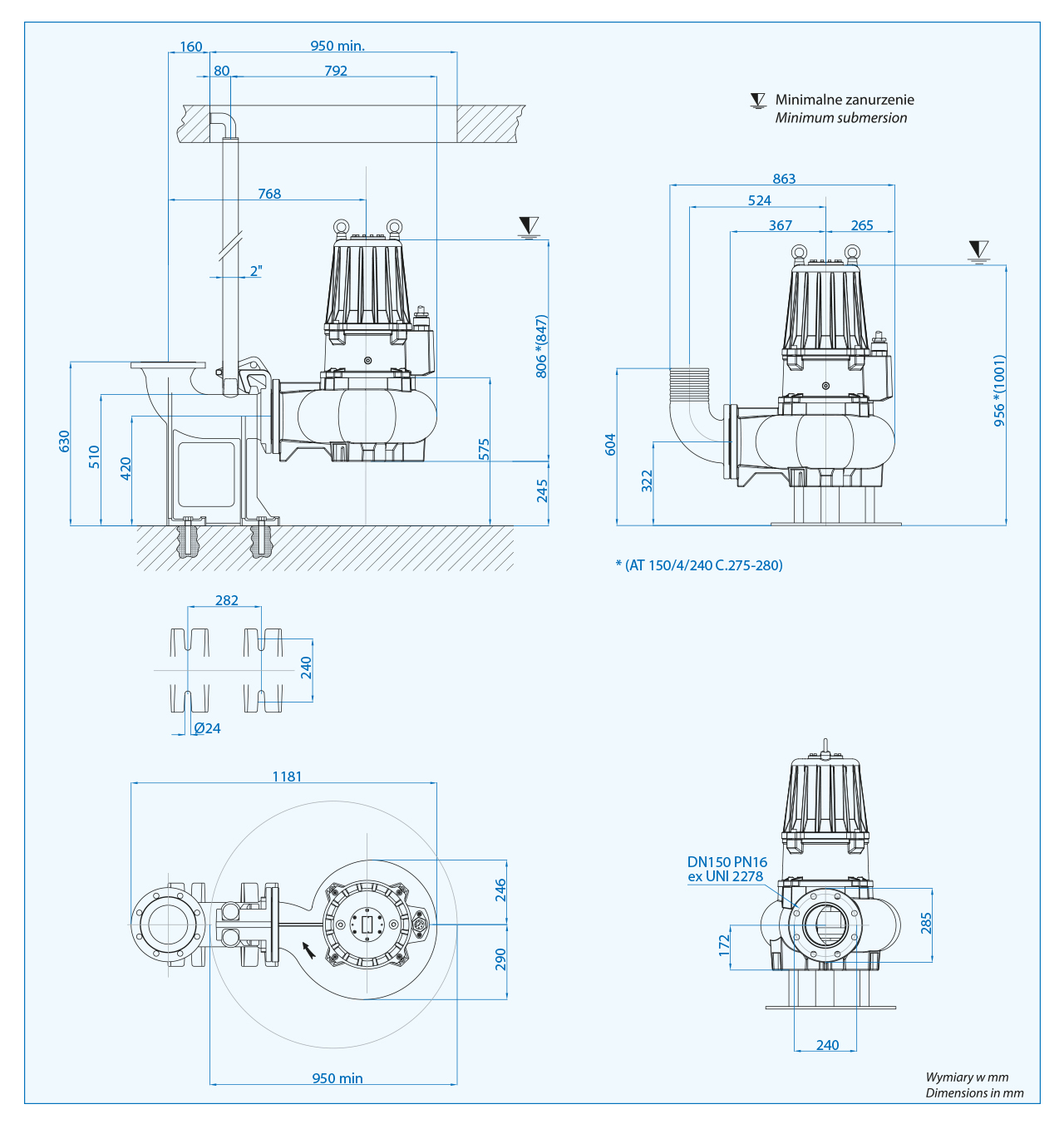

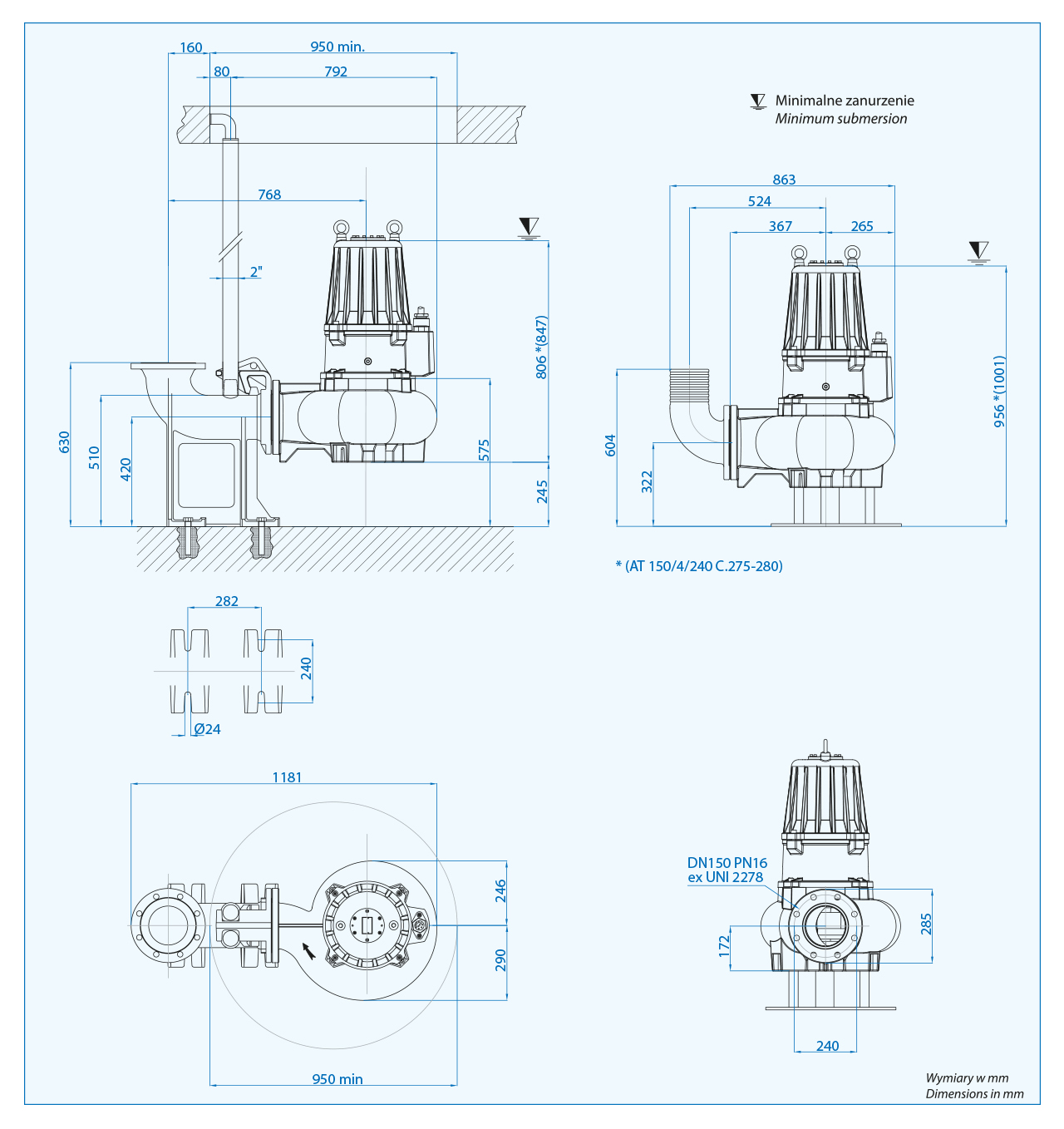

Version 150/4

Version 150/4

Horizontal Outlet DN150 PN16 – RPM 1450 1/min 4 poles

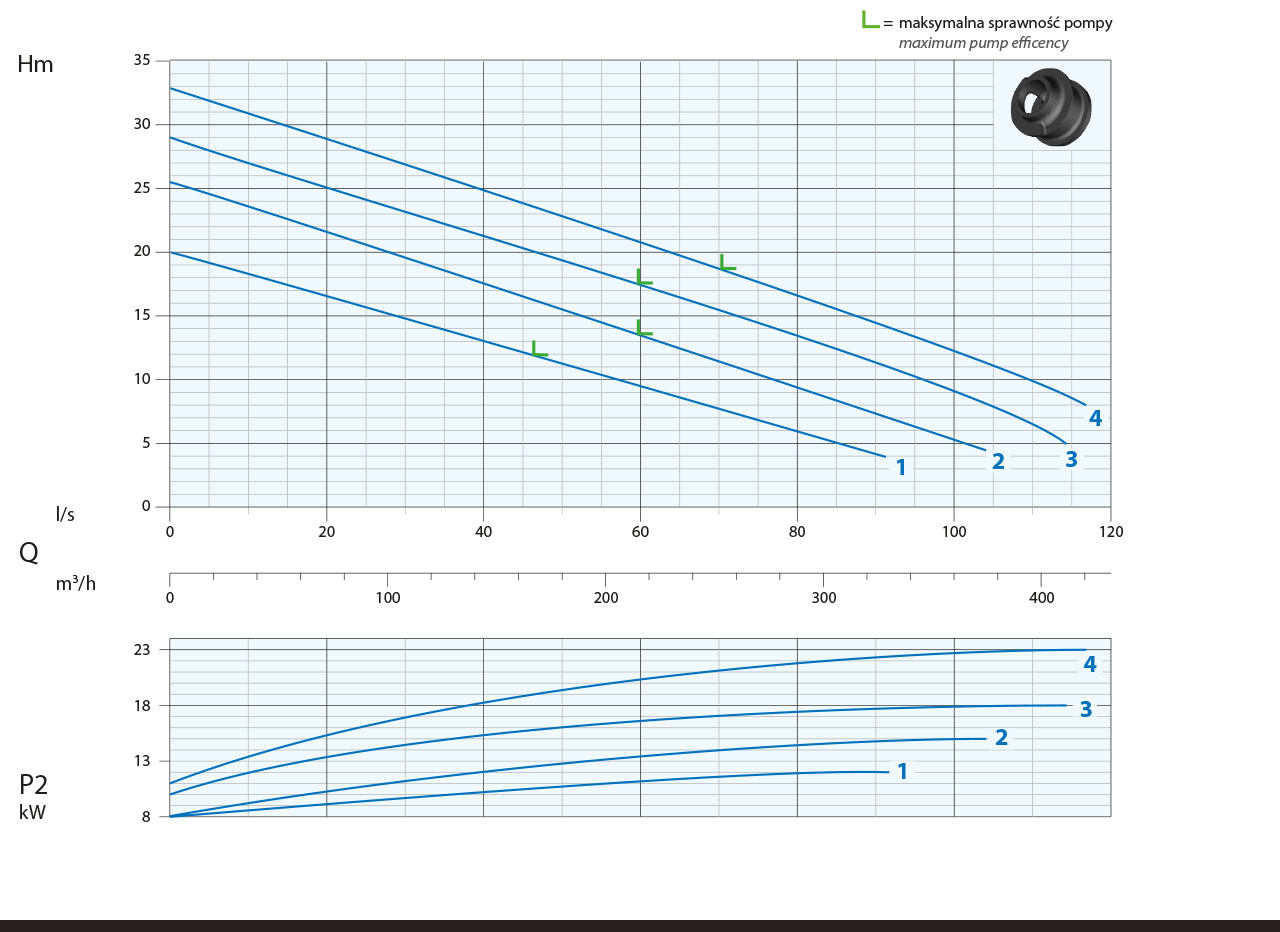

Performance Curve

Technical specifications

Accessories

Automatic coupling foot

Type: B7

Flanged hose connection N4

Foot support P77

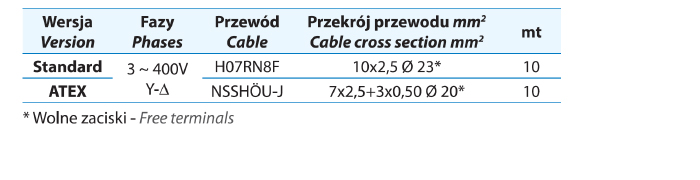

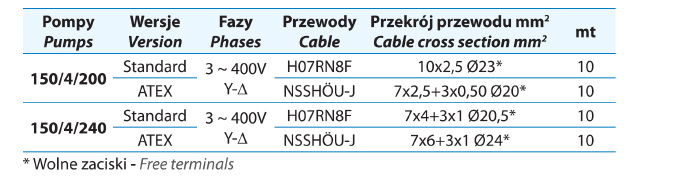

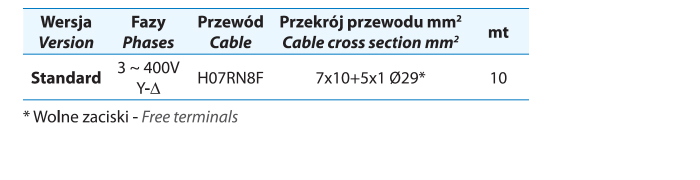

Cables

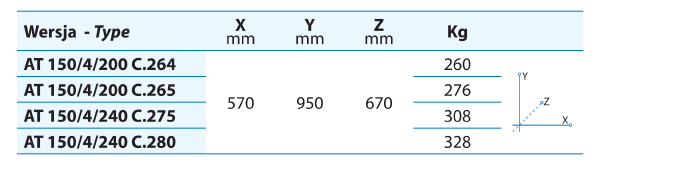

Packaging dimension

150/4

Horizontal Outlet DN150 PN16 – RPM 1450 1/min 4 poles

Performance Curve

Technical specifications

Accessories

Automatic coupling foot

Type: B8

Flanged hose connection N4

Foot support P8

Cables

Packaging dimension

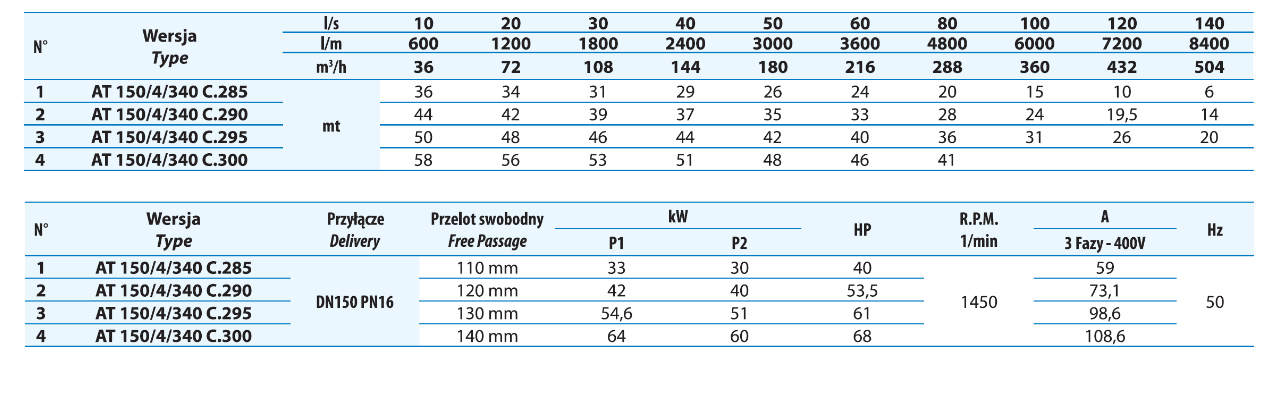

Version 150/4

Horizontal Outlet DN150 PN16 – RPM 1450 1/min 4 poles

Performance Curve

Technical specifications

Accessories

Automatic coupling foot

Type: B8

Flanged hose connection N4

Foot support P8

Cables

Packaging dimension

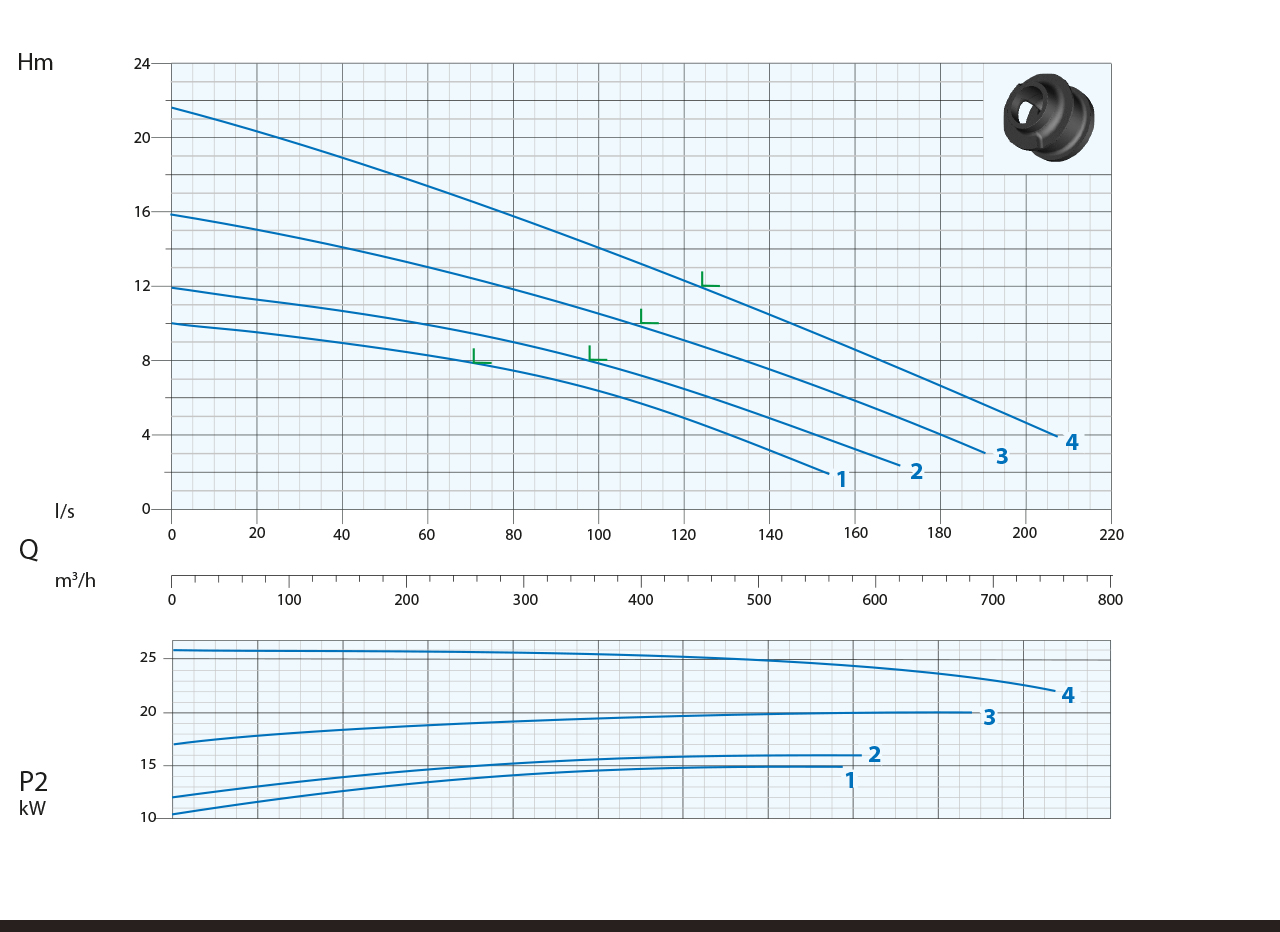

Version 200/4

Horizontal Outlet DN200 PN10 – RPM 1450 1/min 4 poles

Performance Curve

Technical specifications

Accessories

Automatic coupling foot

Type: B9

Flanged hose connection N6

Foot support P9

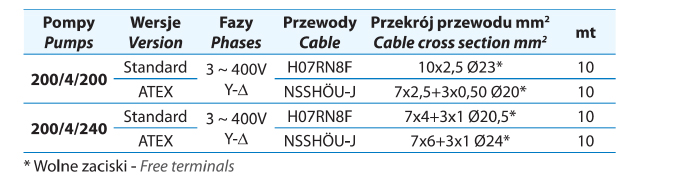

Cables

Packaging dimension

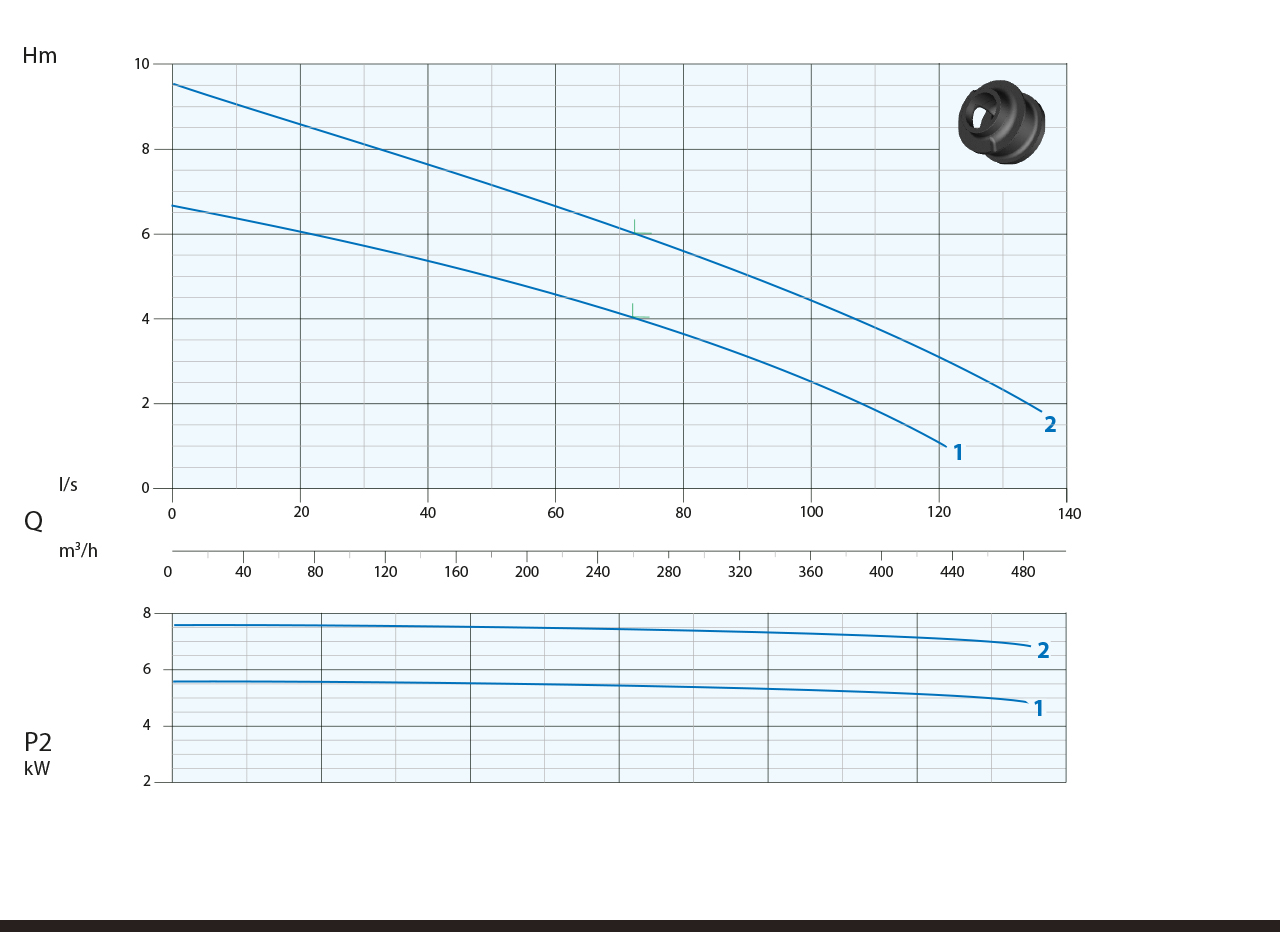

Version A6 200/6

Horizontal Outlet DN200 PN10 – RPM 960 1/min 6 poles

Performance Curve

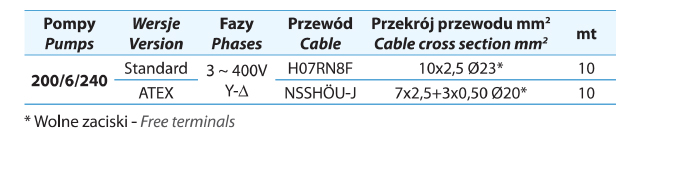

Technical specifications

Accessories

Automatic coupling foot

Type: B9

Flanged hose connection N6

Foot support P9

Cables

Packaging dimension