G2

Download

Product description

Application

The G range has an inbuilt macerator in the inlet. This breaks down solids in waste water which permits transport along relatively narrow, often pre-existing, pipes.

Applications: domestic and industrial sewage, liquids with suspended solids, whenever high pressure (head) is needed

Characteristic

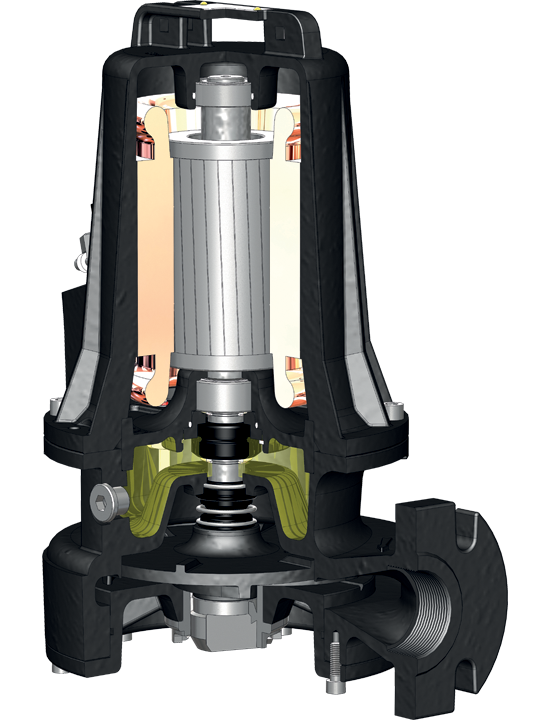

All main components are made of grey cast iron GG25. Two individual mechanical seals (motor side in the oil chamber, impeller side in contact with the liquid) and high quality parts, ensure the perfect functioning and reliability of the product.

Motor range

- Motor range

- Squirrel cage motor at 2 poles

- Thermal protection T1 and T2 embedded in the motor winding (to be wired to the three pole contactor in the control panel)

- Class F insulation (155°C)

- IP 68 protection

Limits of use

- Max. permissible liquid temperature: 40°C with pump fully submerged

- On request, special version (excluded ATEX) to withstand liquid temperature up to 60°C with pump fully submerged, no S1 service

- Maximum depth of immersion: 20 MT.

- Permissible pH value: 6-10

- Hydraulic features suitable for liquids with density <1,1 kg/dm3

- Allowed voltage: 230V/400V-400V/690V ±5%

- Allowed frequency: 50Hz ±2%

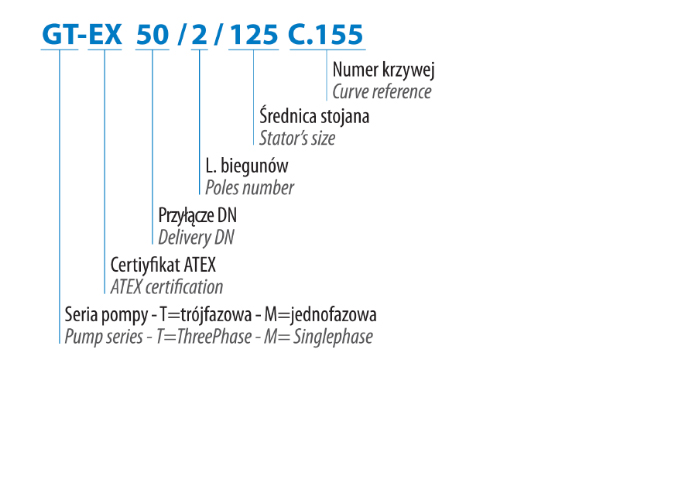

Marking legend

Performance Overview

Performance Overview

List of components and materials

List of components and materials

Cast Iron GG20

Stainless steel AISI 420

Cast Iron GG20

Carbon/Ceramic (CA/CE/Viton)

Silicon/Carbide (SIC/SIC/Viton)

Cast Iron GG20

Cast Iron GG20

Cast Iron GG20

Hardened steel

Technologies and solutions

Technologies and solutions

Grinding system

The pump has a macerator in the inlet with radial and axial cutting action. The blades are made of hardened steel guaranteeing maximal cutting efficiency.

Explosion proof pumps

Pumps with explosion proof available on request.

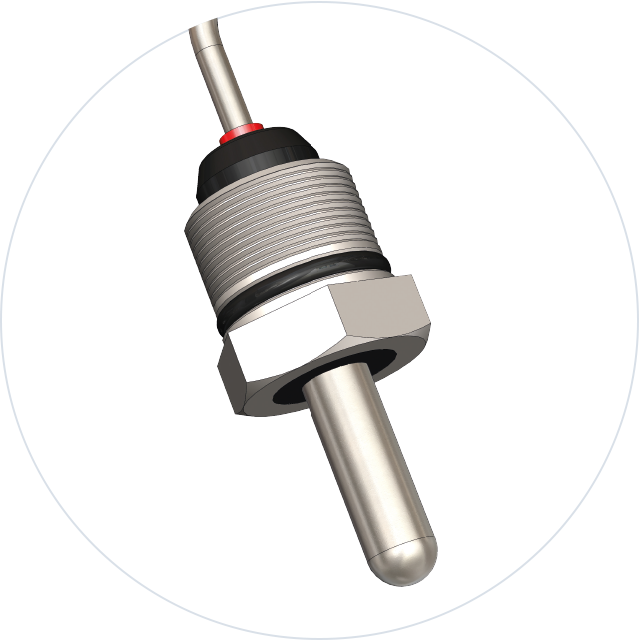

Seal leak detector

The seal leak detector is certified according to the norm ATEX EN 60079-0, EN 60079-1 (through safety barrier) and fitted standard on all series.

Cable gland

The cable gland is made of stainless steel AISI 316 and certified according to the norm ATEX EN 60079-0,EN 60079-1. Standard on all series

Version 50/2

Version 50/2

Horizontal Outlet DN32 and DN50 – G 2” – RPM 2850 1/min 2 poles

Performance Curve

Technical specifications

Accessories

Automatic coupling foot

Type: DUTY 50 and B4/PN6

(only C.165-170)

50/2/125 Thread hose connection G2”

Foot support P1

50/2/152 Flanged curve N1

Foot support P2

Stainless steel handle

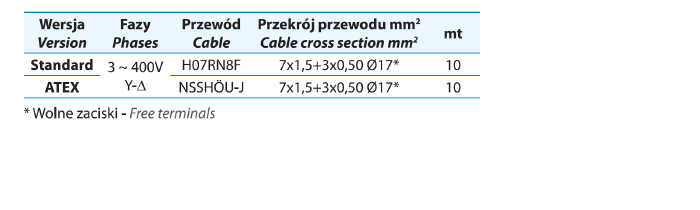

Przewody

Packaging dimension

Version 50/2

Horizontal Outlet – DN50 PN10 G 2” – RPM 2850 1/min 2 poles

Performance Curve

Technical specifications

Accessories

Automatic coupling foot

Type: DUTY 50 and B4

Flanged hose connection N1

Foot support P3

Stainless steel handle

Cables

Packaging dimension